Why Vet New Suppliers?

Obsolescence and product changes may require pivots in procurement. A spate of late vendor deliveries may signal a time for a new relationship. One way or another, every buyer of electronic components will eventually need to vet new suppliers.

Ongoing disruptions and semiconductor shortages have exacerbated these run-of-the-mill issues. Many companies have spent significant effort over the last several years working to identify alternative sources and stockpiles of distributor inventory. This industry is hard at work breaking ground on new fabs and factories worldwide (including 10 new fabs that broke ground in 2022 alone), but this will take time and is not enough to satisfy present demand.

Finding the right parts isn’t easy even without consideration for evaluating them. Electronic component testing services are not just an extra layer to break through, though. A component inspection lab is a critical defense against inauthentic or substandard parts. Many suspect parts have entered the market to try to fill gaps. Turn to certified electronic testing services to guarantee the safety of your investment.

How Can Electronic Testing Services Help?

- Alternative & Replacement Parts: One of the primary reasons to vet new suppliers these days is to evaluate critical second source and like-for-like replacement components when your preferred supplier/manufacturer is no longer an option for whatever reason (obsolescence, out of stock, discontinued service, etc.). Quality assurance, performance, and regulatory compliance testing are key elements of selecting new suppliers with compatible replacement parts.

- Open Up New Sourcing Options: Electronic testing services can open up previously unusable Independent, tier 2, or tier 3 sources by applying the robust quality checks needed to confirm quality and compliance.

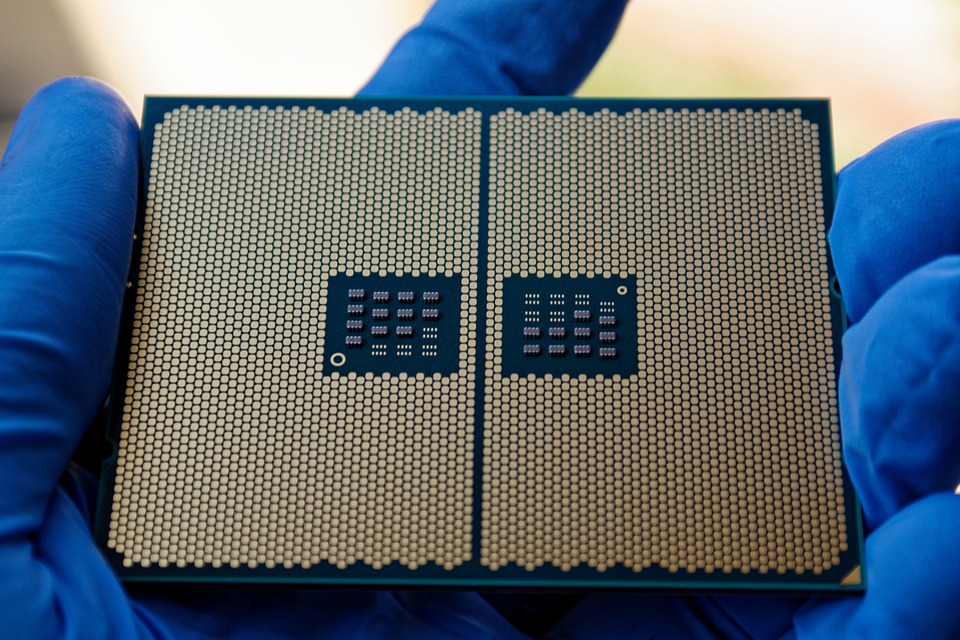

- Counterfeit Detection: Avoid counterfeit ICs in a stretched and disrupted marketplace, especially when working with unauthorized or independent sources to mitigate shortages and fulfill your critical product needs. Make sure to work with an inspection lab that uses IDEA-ICE-3000 certified inspectors and is able to help you develop a custom General Counterfeit Avoidance Test (GCAT) to suit your needs.

- Quickly Expand Your Test Capacity: In-house labs are overstretched and expanding them requires a large investment of time and hard costs for personnel, equipment, and upkeep. Electronic testing services can provide you with a fully outfitted lab to use your way with a custom flow-down inspection or test plan.

- Consolidated Relationships: A hybrid distributor with its own in-house test lab, like Sensible Micro, can provide you with access to a global network of vetted independent, factory-direct, and authorized product lines while also handling your electronic component inspections. Putting all of these supplier and tester relationships under one roof drives efficiency without sacrificing a diverse and secure supply chain.

Do you need a third-party test lab with a discerning eye for vetting new suppliers and sourcing quality parts? Contact Sensible Micro to share the specifics of your project and get information on our robust testing capabilities.

Our partners leverage a worldwide network of vetted sources with only a single point of contact. You can count on our IDEA-ICE-3000 certified inspectors for thorough inspections, including the 72-point IDEA-STD-1010-B visual confirmation procedure that’s still the preferred method of the most quality-driven distributors and OEMs in the industry (as cited in AS5553). We hope to hear from you!