Counterfeit products are present in every industry, and have been a problem for decades. From knock-off luxury or designer merchandise to forged counterfeit electronics, counterfeit items have infiltrated the marketplace and continue to cause economic damage. It is estimated that counterfeit goods cost the global economy approximately $250B USD annually and are projected to represent $991B USD of the global economy by 2022. Economic loss not only affects IPR owner sales but also causes international governments to lose revenues from value-added and corporate income taxes..

Though highly illegal, counterfeiting is a popular black market business due to the fact that imitation goods are usually made with lower quality materials and sold at a marked-up price, making profit margins incredibly high. Almost every product in the global market can be and already has been counterfeited. Counterfeit items are typically made overseas, predominantly in China, prompting the need to test and inspect imported goods and electronic components thoroughly.

Reported counterfeit items pertaining to OEMs & EMS providers include, but are not limited to:

- Electronic components (semiconductors et al)

- Parts used in airplanes, automobiles, and spacecrafts

- Personal-use electronics (tablets, cellphones, headphones/headsets, etc.)

- Electrical machinery and equipment

Fashion, consumer electronics, consumer products, personal care, tech, and toys are among the most commonly targeted industries. In 2018, consumer electronics accounted for 12% of the top counterfeit products seized and critical electronic components accounted for 6% of top health and safety counterfeit products seized.

As an example of the extent to which counterfeiting affects the profitability of the electronics industry, the Intellectual Property Office of the EU (EUIPO) and the International Telecommunication Union (ITU) have reported that smartphone counterfeiting has impacted sales by roughly $52B USD, ~13% of total smartphone sales. In the European, American, and Latin American markets, sales losses have accounted for an upwards of $4B USD per market due to counterfeit goods and counterfeit electronic parts.

Impact of Counterfeit Electronic Parts:

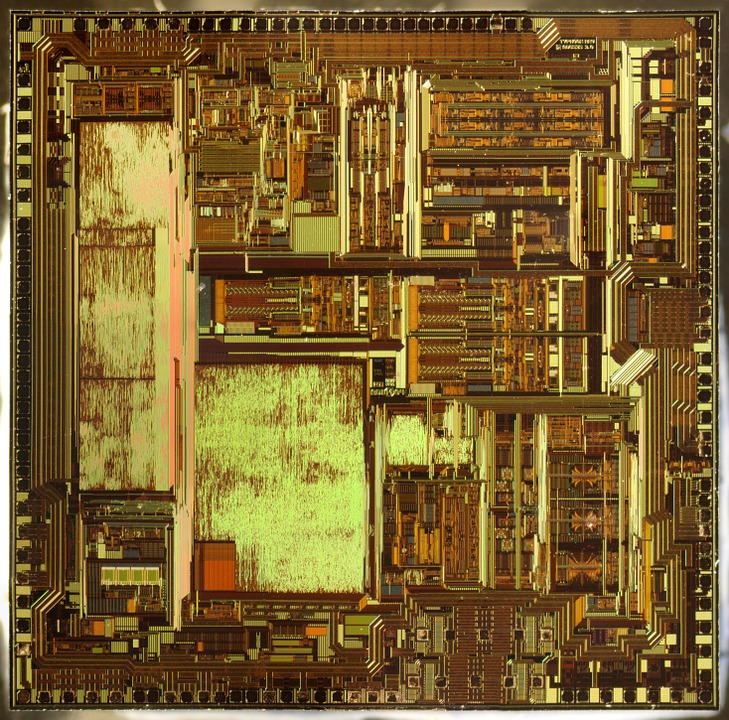

Counterfeit products not only hurt original manufacturers and designers, with illegitimate competition affecting their brand image and bottom lines, but also can cause harm to consumers. When it comes to counterfeit electronics and counterfeit electronics parts, semiconductors are notoriously targeted. Counterfeit semiconductors can jeopardize health, security, and safety while also defacing manufacturing companies and hurting the economy.

When a counterfeit semiconductor is sold in the open market, under the guise of a respectable brand name, it damages the Original Component Manufacturer’s (OCM) reputation even though the sale of the counterfeits is completely out of their control. Counterfeit electronic components also pose a major threat to military systems and operations, as counterfeit electronic components have lower reliability rates.Though the risks for non-military systems are not inherently different, the fact that forged parts find their way into some of the most valued and protected products and systems is speaks to the depth of the counterfeiting problem.

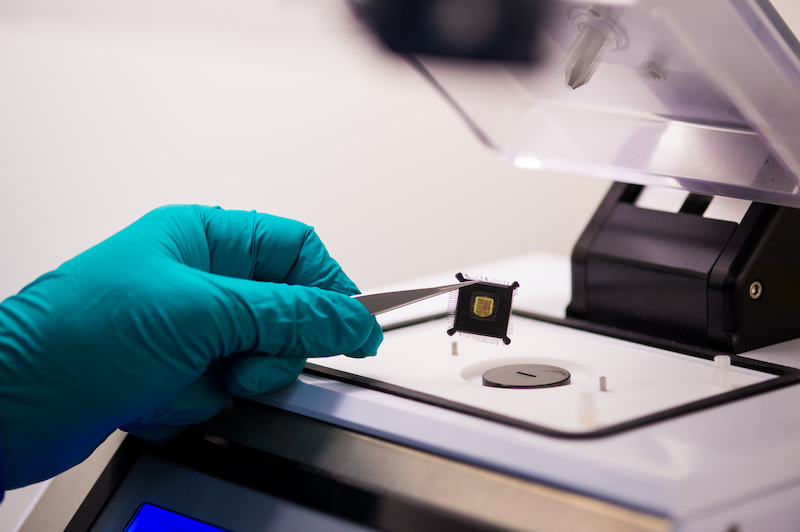

In addition to improving supply chain transparency, supplier communication, and clear guidelines, preventative lab inspection and testing is something all electronic component manufacturers and distributors can do to mitigate counterfeiting issues. Counterfeit electronic components have become more inconspicuous, with external markings identical to those on legitimate products and prices comparable to standard retail value, many in the industry have turned to either third-party laboratories or OEMs and/or CMs with the capability and resources to determine authenticity via access to an electronic component testing lab.

Sensible Micro houses one of the most technically-advanced anti-counterfeit electronic component testing and inspection labs in the industry. We can perform a variety of inspection methods to determine suspect counterfeit electronic components and we have made investments in equipment, standards, training, and staff, so our customers can truly control how encompassing their inspection plan should be by product and end-use criteria.

Additionally, organizations like ERAI were founded to report and monitor issues affecting the global electronics supply chain and although they have helped to educate on the scope of counterfeit electronics, it continues to be a prominent threat.

As a distribution partner to many in the electronics industry, Sensible Micro will continue to provide thorough component testing and work with our vetted supply chain network to ensure the utmost in quality for our customers.

Stay on top of the latest developments in the industry by subscribing to the Sensible Micro blog today.