From capacitors to sensors, microcontrollers to timing devices, original equipment manufacturers (OEMs) and electronics manufacturing service (EMS) providers work with some of the most complex and fragile electronic components and hardware. That means that when placing orders, OEMs and EMS providers typically choose to partner with a franchise or factory direct channel. Of course, there are always going to be times when purchasing from these “normal” channels isn’t possible.

Going Outside the Normal Supply Chain

While most OEM and EMS providers try to stay within their supply chain, there are circumstances when they may be forced to turn to an outside channel. Their usual distributor may not have the item in stock, bringing production to an unacceptable halt. Or perhaps the component needed has become obsolete. Sourcing for these scenarios often means going through excess inventory channels which typically involve brokers and global traders. Since components may have passed through a number of different hands over the years, or been stored for long periods of time, it's very beneficial to visually inspect parts to confirm they are in new condition, with no suspect anomalies found. This is where working with a trusted independent distributor with a quality-driven approach is important.

Working With a “Trusted” Distributor

Often there is a very good relationship between OEM/EMS providers and their independent distributor. This relationship is generally based in good old-fashioned trust—the distributor has a steady track record of delivering high-quality, new, and authentic material, priced right and on time. Along with a good track record, it’s also a good idea to work with an independent distributor that provides actual inspection reporting to help ensure low-quality or even counterfeit products are not introduced into the supply chain.

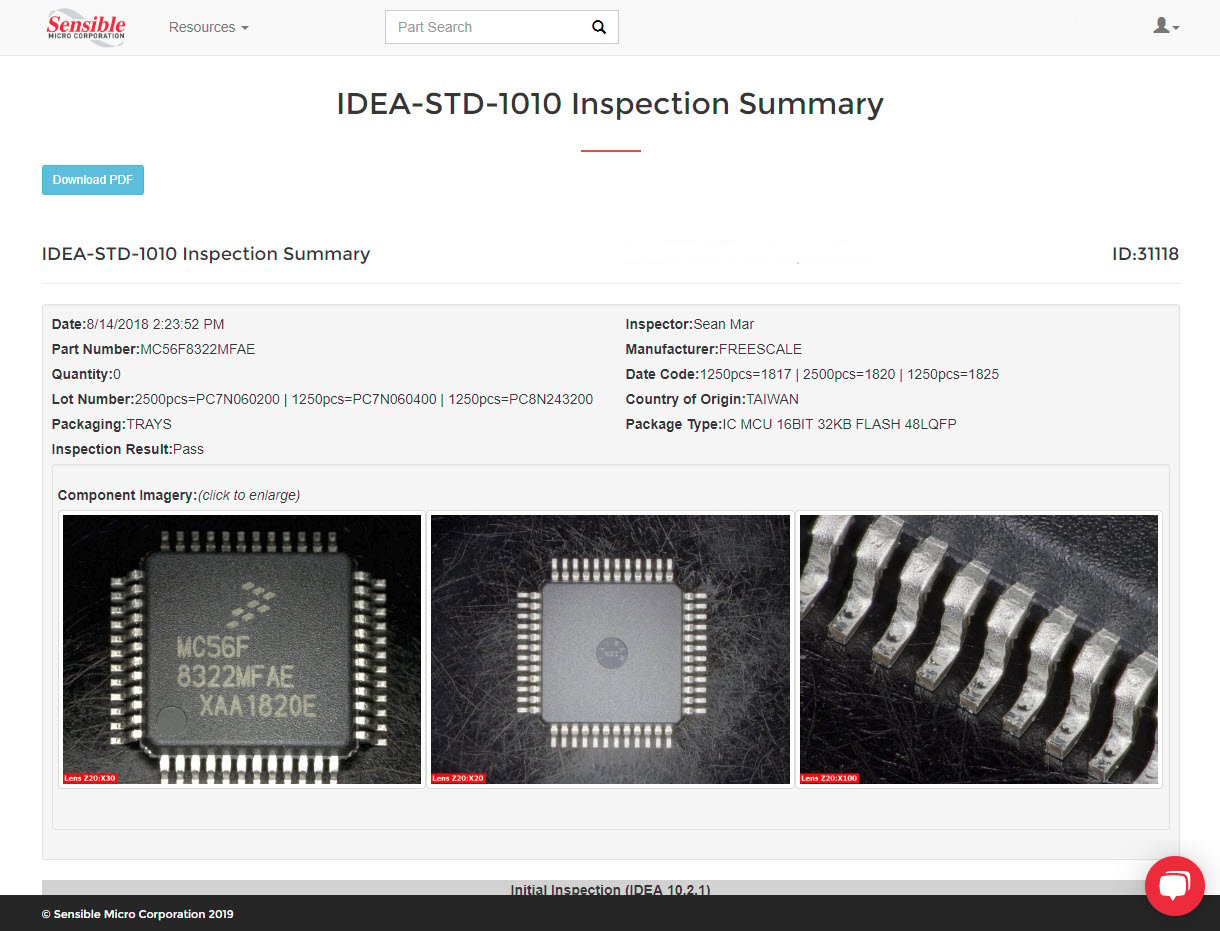

Sourcing With Sensible Micro

Sensible Micro aims to deliver the highest-quality parts and service to our customers through our state-of-the-art lab using the latest inspection techniques. We perform an IDEA-STD-1010-B, a 72-point visual inspection on every single order. IDEA, or The Independent Distributors of Electronics Association, is the leading industry resource regarding quality standards, so no matter if the parts are coming straight from the factory or a third party supplier, our customers can be confident in their quality. All OEM and EMS customers of Sensible Micro also gain access to a unique Sensible Micro portal, where they can download a copy of their IDEA-STD-1010 visual inspection report. The IDEA-STD-1010, or the Acceptability of Electronic Components Distributed in the Open Market, is the first and leading quality standard for the visual inspection of electronic components. It was designed to serve the electronic component industry in detecting substandard and counterfeit components.

Having these visual confirmations upfront enables OEMs and EMS providers to confirm their independent supplier has the protocols, equipment, and experience in place to support their quality goals. This also allows end users to compare known “gold sample” parts against the components they may be sourcing through the independent market.

OEMs and EMSs are welcome to inspect all parts coming from Sensible Micro upon arrival, but we will always provide a quality control inspection report to demonstrate that we have done our due diligence. For more information on our quality control inspection and reports, processes, and objectives, contact a Sensible Micro representative!