Counterfeit electronic components are a major threat to supply chains and remain an ongoing challenge. Although governments and companies have tried to prevent counterfeit electronic parts from entering the market, many manage to slip through. In addition to causing product performance issues for buyers—which can lead to increased maintenance costs and reduced revenue due to damage—the selling of counterfeit electronic components presents concern within the electronic manufacturing industry about genuine economic and innovative growth.

In 1995, ERAI was founded to monitor and report on issues affecting the global electronics supply chain—and though they have helped to educate on the scope of counterfeit electronics, it continues to be a prominent threat. The best way electronic supply chains can detect the existence of suspect counterfeit electronics is by using industry adopted inspection methods to examine for discrepancies. Here are four common, yet effective, techniques that help suppliers discern counterfeit electronic parts from their authentic counterparts.

Visual Inspection

Counterfeit electronic components had very basic inconsistencies in the past that were easily visible to the human eye, such as spelling errors and slanted and faded wording. However, advancements in counterfeiting have been made, making the discrepancies harder to spot. A slideshow from ERAI gives a full list of common visual imperfections, along with other counterfeit data, and suggestions on how to spot irregularities in today’s counterfeit electronic parts market.

An electronic components sizing measurements—height, length, and width—should match the product specifications documented on the OCM datasheet. During visual inspection, all measurements need to be confirmed from actual body dimensions to lead spacing, as well as the component markings and mold cavities observed.

Counterfeiters will sand down the surface of the part to remove any original markings, and then resurface the material in a process known as “blacktopping”, to reprint the fake numbers and details. Performing an Acetone wash should remove the added remnants and reveal the original markings as well as Heated Solvents Testing for more aggressive surface inspection.

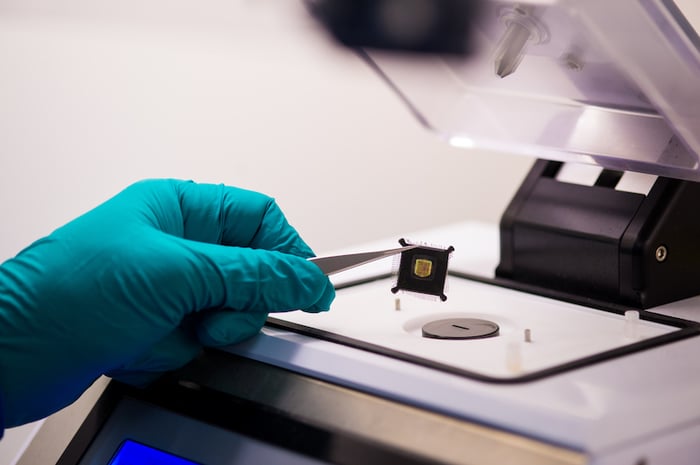

X-Ray Inspection

X-ray inspection of electronic components allows suppliers to examine the inner workings of the part, such as the die frame and wire bond integrity. According to an ECN online magazine article, the six most common irregularities within the counterfeit electronic part include:

- Inconsistent die sizing

- Inconsistent lead-frame

- Broken or missing wire bonds

- Incorrect wire-bonding diagram

- A missing die

- Variations in the die attach bonding

It is much easier to counterfeit an electronic parts exterior than the interior. That is why X-ray inspection is a useful method for detecting discrepancies and comparing it to manufacturer specifications against a golden sample part.

Electrical Testing

U.S.-Tech defines electrical testings as a counterfeit parts procedure for measuring the functional and parametric requirements at the recommended extreme operating temperatures. Numerous tests are run to check the direct current (DC), the alternating current (AC), and the functional performance of the electronic component. The intricacies of the tests provides suppliers and customers with enough robust data to uncover a counterfeit microchip than other test methods.

There are five industrial categories that use electrical testing for counterfeit products:

- Commercial- Performing in temperature ranges 0 to +70° C.

- Industrial- Testing in temperature ranges -40 to +85° C.

- Automotive- Perform functional testing over the temperature range of -45 to +110° C.

- Military and aerospace- Subgroups 1, 2, 3, 4, 5, 6, 7, 8A, 8B, 9, 10, 11 performing in temperature ranges -55 to +125° C.

- Space- Subgroups 1, 2, 3, 4, 5, 6, 7, 8A, 8B, 9, 10, 11 testing in temperature ranges -65 to +150° C.

Decapsulation

Decapsulation testing is performed by using a variety of acids, bases, and solvents to remove the mold compound covering the die. This allows suppliers to view the inner workings of the electronic part with a high-powered microscope to visually inspect for irregularities in the manufacturing. To ensure that electronic parts are authentic, suppliers should verify the following:

- There are correct manufacturing markings

- There are no defects to the die or wire bonds

- Any typography is correct

- All parts and numbers are accurate and authentic

Identifying counterfeit electronic components is difficult since there could be more than one reason for a component failing the necessary testing. Manufacturers can use older production parts for upgraded newer production runs, sometimes the OCM will remark the components themselves, so not everything that looks suspect is a potential counterfeit electronic part. Only the factory itself has IP authority to call a part counterfeit—the term used by everyone else in the industry is "Suspect Counterfeit." While a part can be blatantly fake, only the IP holder can legally make this claim.

Ordering your components from the right electronics supplier, protects your investment and products from costly repairs caused by component failures. Sensible Micro is an ISO 9001:2015, AS9120B, CCAP-101 and IDEA-QMS-9090-B certified distributor where we make it our goal to increase the value of our customer’s supply chain. Our technically-advanced inspection lab performs full counterfeit avoidance testing with the focus on ridding your supply chain of counterfeit or suspect electronic supplies and components, while delivering exceptional customer service.

Contact us today to help meet your business needs!

Stay on top of the latest developments in the industry by subscribing to the Sensible Micro blog today.