An ISO certification certifies a distributor’s management system, processes, and services follow a set list of international quality standards that efficiently meet customer demands. These certifications exist in many industries—from aerospace to energy management. Certain OEMs and EMS providers will even require distributors to have an ISO certification in order to sell to them.

ISO standards give distributors a layout of what quality guidelines they must meet for every order they process. Without following the proper quality control processes, distributors can deliver subpar or defective components to their customers and increase the risk of having other quality standard issues by failing to continuously improve their services.

It’s not surprising to see how valuable it is for distributors to have an ISO certification. But how else can this certification improve distributors’ quality management systems?

Here are some examples of how these ISO standards help electronic component (EC) distributors follow and improve their quality guidelines.

#1 Helps Distributors Continuously Improve Quality Assurance

Distributors with an ISO certification are required to identify and describe their quality management system (QMS) processes using business metrics. By gaining a better understanding of their services, distributors learn more about their own business and can ensure their QMS is meeting customer demands. These metrics are used to understand a distributor’s QMS and how it helps them meet their quality assurance objectives.

An ISO certification makes sure distributors are finding new ways to continuously improve their quality control processes. It also requires distributors to have a disaster recovery plan, so in case there’s a situation that drastically affects their facility, distributors can still fulfill their customer’s orders.

#2 Improves Consistency of Quality Control Services

Adjusting quality control services is often necessary for distributors to meet changes in customer demand or keep up with advancements in their own business. However, the overall consistency of these operations, and the ability to maintain quality guidelines, should never be altered.

A working QMS should include a clear target objective that has distributors collect data on their quality control processes and understand what adjustments are needed to maintain the target output. With better process integration, distributors eliminate process waste and reduce the risk of quality errors to achieve greater, tangible results.

#3 Internal and External Audits Ensure Quality Objectives are Continually Followed

It’s easy for a business to lose focus on their quality objectives over time—that’s why internal and external audits are a great way for distributors to monitor their QMS. They can be done on-site or remotely, but remote audits are less common. By providing feedback on issues affecting service performance, distributors can avoid and correct any actions that go against their quality assurance.

External audits can be performed by auditors brought in by the distributor or by an existing customer that wants to be sure they are meeting their requirements. Internal audits can be performed by trained employees with the proper certification and are required for distributors to receive an ISO certification. These audits ensure quality guidelines are being followed, evaluate the effectiveness of quality control procedures, and assess conformity.

#4 Establishes a Mutually Beneficial Distributor/Customer Relationship

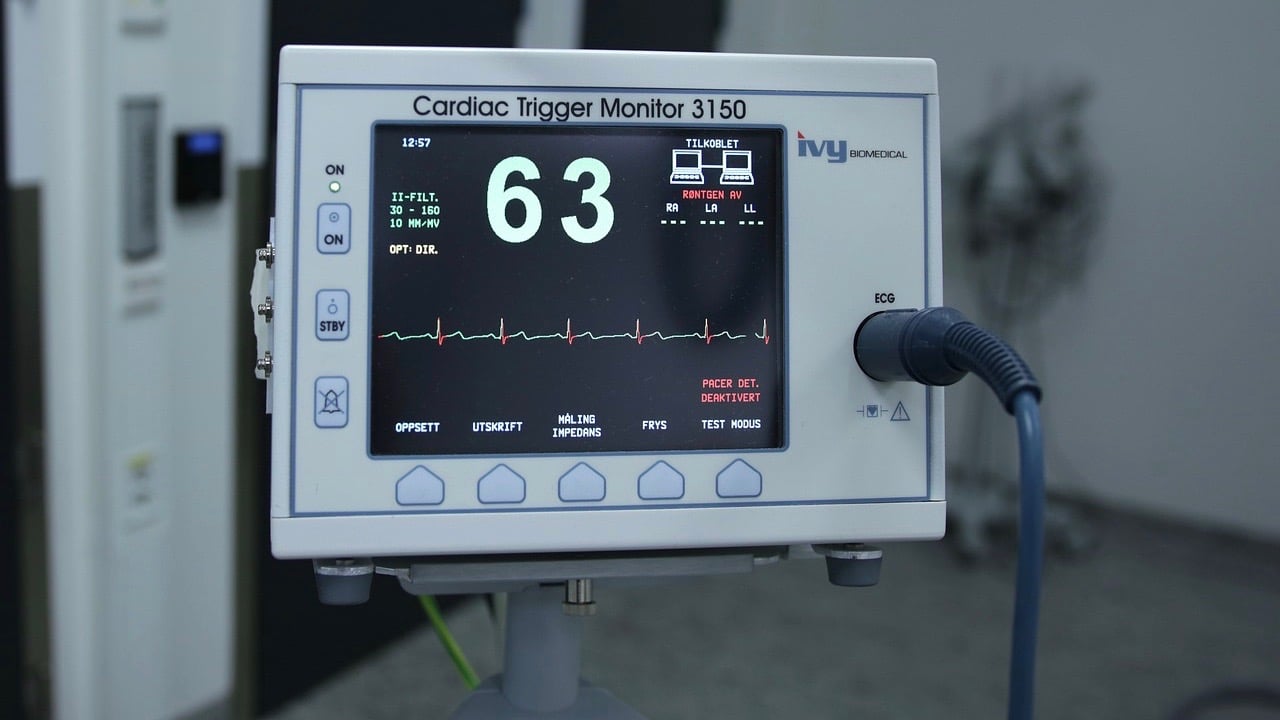

It’s just as important for customers to work with a reliable, consistent distributor as it is for the distributor. Searching for a distributor committed to following quality standards outlined for their services can be difficult, and can start to become costly for customers switching from one distributor to the next. Plus, distributors rely on positive customer reviews in order to gain more clients and revenue. A distributor with an ISO certification assures customers that they can expect quality products being delivered and have received the proper inspections and testing that meets ISO quality guidelines.

Sensible Micro is a certified ISO 9001:2015 distributor that also provides inspection and testing services to mitigate and avoid supplying customers with substandard, suspect counterfeit or defective components which could stop or slow normal supply chain operations. For information on our range of quality management services and policies, contact a representative today!

Stay on top of the latest news, trends, and developments in the industry by subscribing to the Sensible Micro blog today.