COVID-19 was a major catalyst for the global supply chain disruptions and shortages that have grown increasingly complex and costly since early 2020. According to Accenture, 94% of Fortune 1000 companies are seeing supply chain disruptions from COVID-19. Few industries have been left unscathed.

But which have been the hardest hit? While the pandemic has affected most businesses in some fashion, these seven industries have suffered the worst effects of the upheaval in the supply chain.

The 7 Industries Most Impacted By Supply Chain Woes

Pretty much anything that’s produced or manufactured is in short supply. Every shortage begets another one. As the NY Times pointed out, “a paint manufacturer that needs 27 chemicals to make its products may be able to buy all but one” and that alone can be enough to halt production.

The White House released figures in June 2021 that estimated the supply chain disruptions felt by various economic sectors, with manufacturing topping the list.

This is of little surprise. Factories that create raw materials, components, and assembled parts for various products were some of the hardest-hit businesses by shutdowns, health concerns, and rapid fluctuations in capacity, demand, strategy, and workforce availability.

However, sectors are broader than industries. In general, it’s clear that businesses working with physical goods were more impacted than services. CNBC identified six out of the following seven industries as experiencing the brunt of the supply chain fallout. We’ve added a seventh based on additional data from Statista.

1. Automotive

There’s no way around it in 2021 — cars need computer chips. Too many automakers cancelled shipments of chips at the start of the pandemic, anticipating a sag in demand that never truly materialized or didn’t last nearly as long as predicted. Now, with demand through the roof and the semiconductor shortage throwing a wrench in the works, it’s become much harder and more expensive to produce (or buy) cars.

McKinsey reports that many automakers have announced billions of dollars in expected revenue losses due to curtailed production and no solution in sight to the lack of automotive semiconductors.

2. Footwear and Apparel

The retail clothing, footwear, and fashion industries have had a costly struggle with supply chain issues and other pandemic-related fallout. The McKinsey Global Fashion Index, for instance, reports that apparel companies lost more than 90% of their profits in 2020. Shipping delays and shortages of raw materials aren’t helping matters. Nearly 60% of retail companies are reporting a severe shortage of supplies or inputs.

3. Food and beverage

Across all industries, the national average number of companies reporting shortages in the supply chain is 36%. Food and beverage businesses come out well above that mark, and are third-worst overall; half of all food services reported a shortage of critical supplies.

4. Manufacturing

Manufacturers and distributors of goods have experienced ramifications of not only unavailable raw materials or key components, but a massive labor shortage to boot. With not enough workers to ramp up to meet high demand and not enough materials to produce goods, manufacturers are under extreme pressure during the supply chain fallout of 2021.

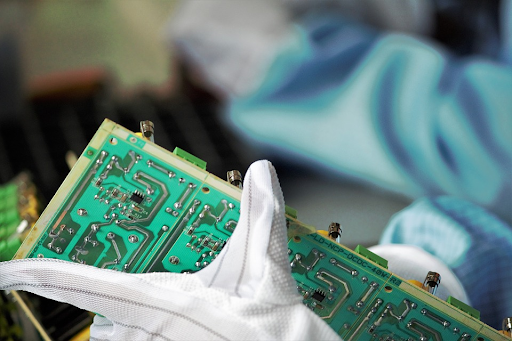

5. IT, Tech and Electronics

Consumer tech saw a huge uptick in demand during the pandemic as folks sheltered inside and turned to electronics for recreation, work, and connection to the outside world. With the semiconductor shortage simultaneously raging out of control, it’s not shocking that the tech industry has been among the hardest hit. The latest IHS Markit Global Electronics Purchasing Managers’ Index makes this clear. Global electronics manufacturers are facing extreme delays on orders from their suppliers, with each new month extending the all-time record for highest lead time.

6. Healthcare, Pharmaceuticals and Biotech

Nearly two thirds (64%) of healthcare companies have reported a shortage of supplies. Heath, pharma, and biotech companies have been among the hardest hit by supply shortages as demand for their services has skyrocketed at the same time as many vital links in the supply chain were cut off. Medical devices, in particular, have struggled to find the necessary electronic components for critical products like ventilators and other specialized hospital equipment.

7. Telecommunications

After healthcare, telecommunications is the industry next-most impacted by supply chain issues, in terms of business outcomes. This industry encompasses IoT, cloud computing, the rollout of 5G networks, and other internet and communications services highly dependent upon the semiconductor supply chain ecosystem.

A new report from telecom research consultancy STL partners suggests that the production of smartphones, smart speakers, routers, and IoT devices has been deeply disrupted — and this could well continue into 2023. As it is, ISPs are facing a delay of 60 weeks (14 months) just for broadband routers.

Facing Supply Chain Issues? We Can Help.

Supply chain disruptions have now overtaken the COVID-19 pandemic as the biggest obstacle to domestic and corporate growth. If you’re having trouble locating a reliable supply of high-quality electronic components, contact the Sensible Micro team. Our hybrid line card offers resiliency, with authorized, direct, and independent options for the parts you need.