As the multilayer ceramic capacitor (MLCC) shortage is projected to continue through 2020, many OEM and EMS companies can expect longer lead times and delays from suppliers. This shortage is due to the increased allocation of MLCCs for use in smartphone, camera, and automobile manufacturing. This increased demand for MLCCs has pushed lead times from many suppliers and distributors as far back as 40 weeks.

Key updates to major end-user electronics company product lines over the past two years has caused the demand for MLCCs to spike exponentially. The production of the Apple iPhone® X, which doubled the requirements from 500 capacitors needed in the iPhone® 6s model to around 1,000 capacitors per handset in its latest iteration, has placed a strain on the supply chain. Automobile manufacturers like Tesla also top the list, requiring 9,200 capacitors per unit of its Model 3.

The demand for MLCCs has put more strain on suppliers who are hesitant to increase production due to the slim profit margin associated with production. Murata, a top manufacturer of MLCCs, announced it will increase production by only 10% and will raise prices between January and April of next year. To compound difficulties even further, an unintended consequence of this shortage has caused an uptick of counterfeit MLCCs in the market.

All this over a passive component that costs less than a dollar to produce. As end-user electronics companies like Apple, GoPro, and Tesla continue to develop new product lines each year, it can be hard to predict what will be the next cause of a component shortage. However, there are inventory and supply chain management strategies that can be used to avoid component shortages. Let’s explore some options.

Have Multiple Vendors on Your Approved Vendor List (AVL)

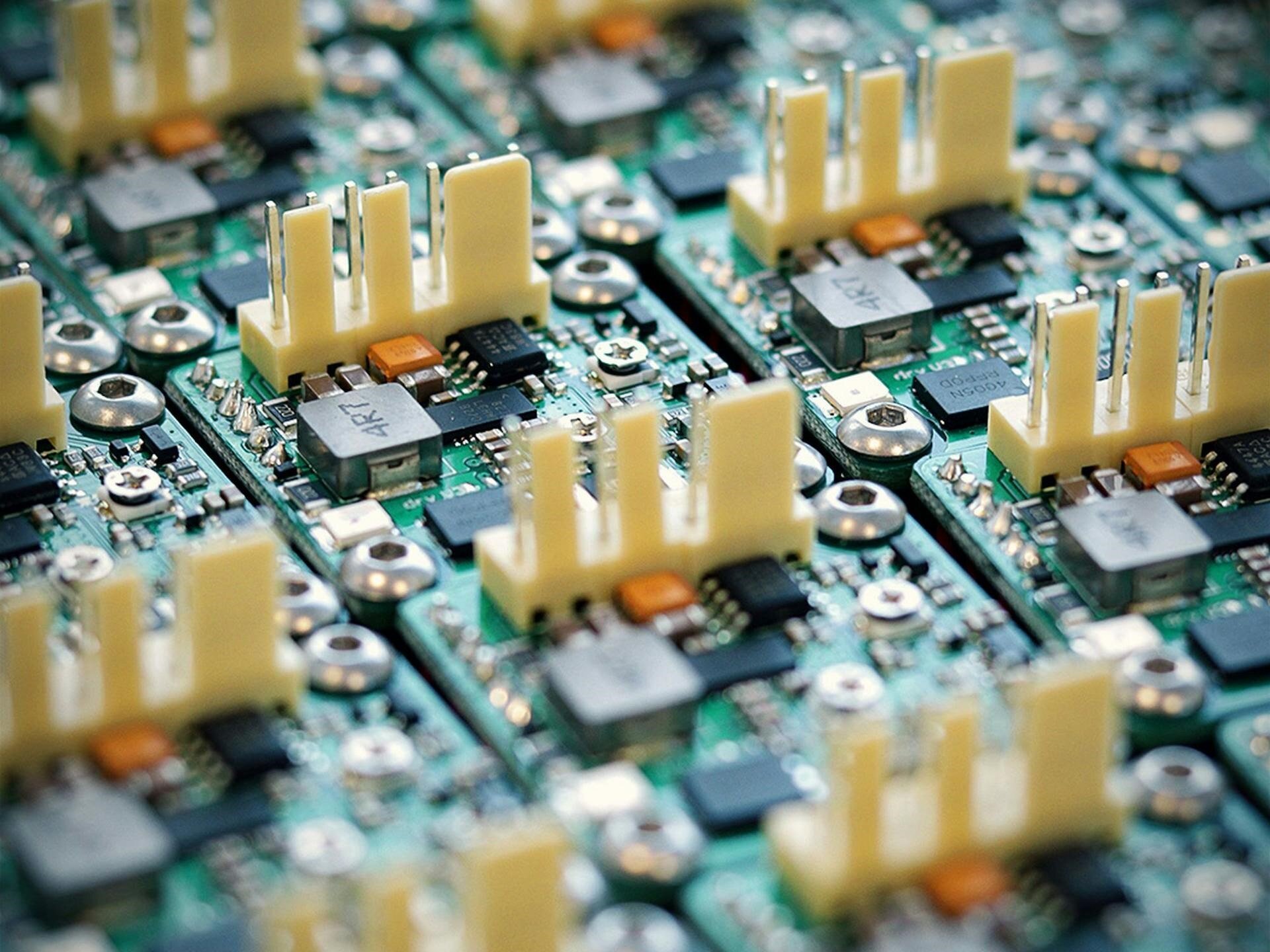

While there are many causes of the latest multi-layer ceramic capacitor shortage, allocation is a huge leading factor. Suppliers allocate a proportion of their output to certain manufacturers/vendors when there is a shortage. This means that each might get less of their required supply.

In times of unexpected shortages, it’s important to have already set up alternative vendors on your approved vendor list (AVL), especially if supplier allocation is causing issues. In the case of specific parts such as MLCCs, you want to look at vendors that have the correct certifications and can provide quality sourced parts to avoid suspect counterfeit components.

At Sensible Micro Corporation, we have ISO 9001:2015, AS9120B, IDEA-QMS-9090, IDEA-ICE-3000, ANSI/ESD S20.20, and CCAP - 101 quality assurance certifications, as well as memberships with ERAI and GIDEP. We also have an on-site inspection and test lab which uses state-of-the-art technology such as XRF analysis, parametric electrical testing, decapsulation, void analysis, and more to check for suspect counterfeit or substandard components.

Learn more about why Sensible Micro Corporation makes sense to add to your AVL.

Scheduled Stock

While it’s multi-layered ceramic capacitors today, there could be another passive component shortage crisis tomorrow. When companies need component sourcing solutions during times of shortages, they should look into proactively setting up a stocking plan with your supplier to include bonded inventory.

Scheduled stock to help minimize on-hand inventory is a good practice all the time, but it’s especially crucial during shortages. OEMs and EMS providers can work with suppliers to store bonded inventory in their warehouses and ship when needed. If buyers already have a stocking plan in place with their suppliers, they won’t have to worry about shortages since their needed supply is accounted for in bonded inventory.

Consider Alternative Components

The increasingly frustrating aspect of the multi-layer ceramic capacitor shortage is that it’s caused by a specific component that can be replaced by an equally rated capacitor like tantalum capacitors. The main differences between tantalum capacitors versus ceramic capacitors are performance under certain temperature and voltage differences. In many applications, tantalum capacitors can be used in place of MLCCs however tantalum may increase the cost of the components.

Before the next unexpected component shortage shakes up the global supply chain, buyers and product engineers should plan for the substitution of alternative component options in schematics as a stopgap during a time of shortage. Now, due to the shortage of MLCCs, the demand for tantalum components is beginning to increase as well. The lesson learned here is to consider multiple alternative component options to compensate for the shifting demand for secondary replacement components.

Although the MLCC shortage is expected to continue for at least another year, there are ways to circumvent the loss of production due to component shortages. At Sensible Micro Corporation, we maintain a global sourcing network and a wide variety of components in stock for shipment. If you’re looking for MLCC solutions, get in touch with one of our sourcing solutions experts now.