Inventory demand forecasting has been especially difficult over the past few years. With shifting customer demands and uncertain supply chains, getting the right mix of materials, components, and products on hand has been a challenge.

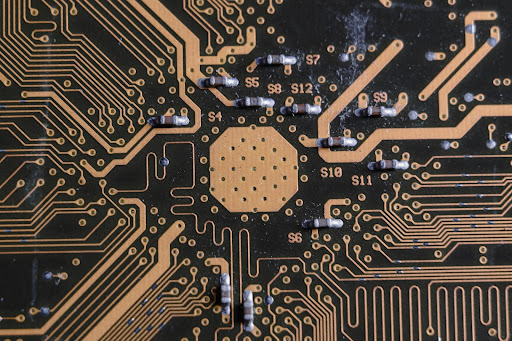

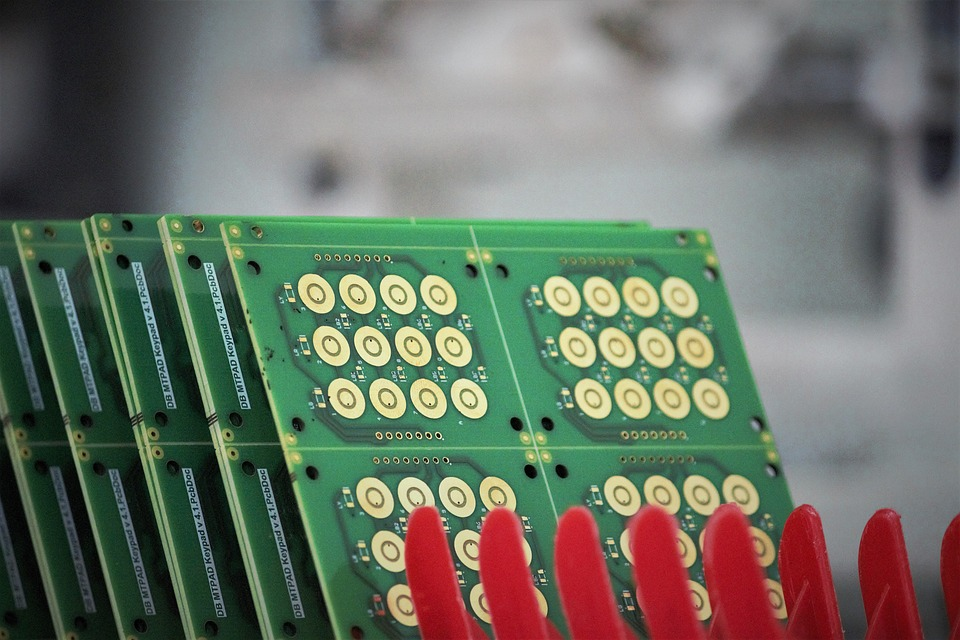

With electronic component inventory management, raw materials and component shortages along with suppliers’ inability to deliver the products you need on your schedule has caused significant disruption. In today’s environment, manufacturers need a diverse source of suppliers and partners they can trust to help them meet demand.

A closer look at how demand forecasting and inventory management work together can help. Here’s why you can no longer rely on just-in-time (JIT) strategies to manage inventory during changing demand cycles.

Demand Forecasting and Inventory Management

Demand and inventory planning go hand-in-hand. If you miss on either, your cash flow suffers.

Demand Forecasting

Demand forecasting is the planning process to anticipate customer demand, such as during seasonal peaks. With an accurate forecast, you can better plan to meet that demand and mitigate risk.

Inventory Management

Inventory management ensures you have the materials you need when you need them to meet demand. Proper inventory management is essential to limiting stockouts or overstocks.

Accurate demand and inventory planning can help maintain the right number of components and products to meet demand without tying up excess capital in inventory you don’t need.

Just-in-Time Is No Longer the Answer

However, reliance on a just-in-time strategy no longer works. The uncertainty in the supply chain means JIT methods may not allow you to fulfill orders, especially when there are supply chain disruptions, shortages of materials, and spikes in demand. When demand is high, you must have a steady supply of the materials you need.

While you don’t want to stockpile components you may not need, you can’t afford to get caught short-handed either.

Improving Demand Forecasting and Inventory Management

There are two key components to improving your inventory demand forecasting:

- Being closer to your customers

- Planning for the unexpected

The closer you are to your customers and the more you understand how they anticipate demand, the more accurately you can predict your needs. Since products often have several downstream producers, tracing what happens to your products after you send them to your customer can also help you to better forecast demand.

You also need to plan for the unexpected supply chain issues. Do you have a plan in place in case of:

- Sudden shortages in components or materials

- Regular sources are no longer available

- Components are delayed or back-ordered

- Supply chain disruptions from transport and shipping

- Global unrest and changing government restrictions

In short, take planning seriously and have a backup plan in case something unusual occurs.

Managing Inventory During Demand Spikes and Drops

Mitigating availability issues requires proactive inventory management and demand planning to manage spikes and drops. Because you can no longer assume you can get the components and materials you need on demand, manufacturers are taking additional steps to protect themselves, including:

Procuring Second Approved Sources

Having a second source on your approved vendor list (AVL) is more important than ever. The more specialized or customized the electronic component is, the more important this becomes.

Sourcing the Open Market

You may need to find sources on the open market, but there are challenges. For example, global chip shortages have led to an increase in counterfeit and relabeled products. You need an electronic components distributor like Sensible Micro which has a state-of-the-art testing lab to verify authenticity.

Adjusting Safety Stock

Carefully manage safety stock so that it’s not too expensive during periods of low demand, but leaning into it during spikes or high demand forecasts.

Planning for Obsolete Components

Sourcing becomes a lot more difficult once parts are no longer in production. Manufacturers should pay close attention to Last Time Buy (LTB) notices and consider stocking up, transitioning away from obsolete components, or finding a viable alternative part or source.

Work with a Distributor You Can Trust

When you work with a trusted distributor that understands your business, you have the peace of mind that comes from knowing you can get what you need. Sensible Micro has a large selection of in-stock inventory and a global network for vetted suppliers. If you need to find alternative sources amid shortages or need to offload excess inventory, the experts at Sensible Micro can help.

Get in touch with Sensible Micro Corporation today to discuss your electronic components sourcing needs.