Supply chain inefficiencies impact OEM bottom lines, increase procurement risks, and create unnecessary operational bottlenecks. Implement a smart supply chain optimization strategy to keep component costs down and gain better control over your inventory.

The High Cost of an Inefficient Supply Chain

Without a streamlined supply chain, OEMs face cost pressures from multiple angles. Overstocking leads to unnecessary holding costs and the risk of component obsolescence. Last-minute emergency orders drive up costs with rush fees and limited supplier options. Poor forecasting and inventory mismanagement result in expensive expedited shipping.

According to an Annual Global Supply Chain Report from Interos, organizations — on average — lose $182 million in revenue annually due to supply chain disruptions. However, only 11% of organizations continuously monitor supplier risk.

All of these strategic challenges and planning missteps can impact margins. However, with proactive supply chain cost reduction strategies, OEMs can cut waste and improve profitability.

Cost-Saving Strategies for OEMs

Supply chain optimization will reduce procurement and operational expenses. Consider these three areas when evaluating your supply chain strategy:

1. Efficient Inventory Management

Strategic inventory planning can help your company stock the right components without over-purchasing or underestimating demand.

- Just-in-Time (JIT) Inventory: The JIT approach reduces carrying costs because you only receive parts when needed — but this is best reserved for reliable supply lines of current, widely available components.

- Buffer Stock for High-Risk Components: A buffer stock keyed to component-specific risk levels helps to mitigate shortages while avoiding the costs and inefficiencies of unnecessary stockpiling.

- Vendor-Managed Inventory: A knowledgeable supply chain partner can take inventory logistics off your plate and manage levels effectively to prevent overstock and shortages.

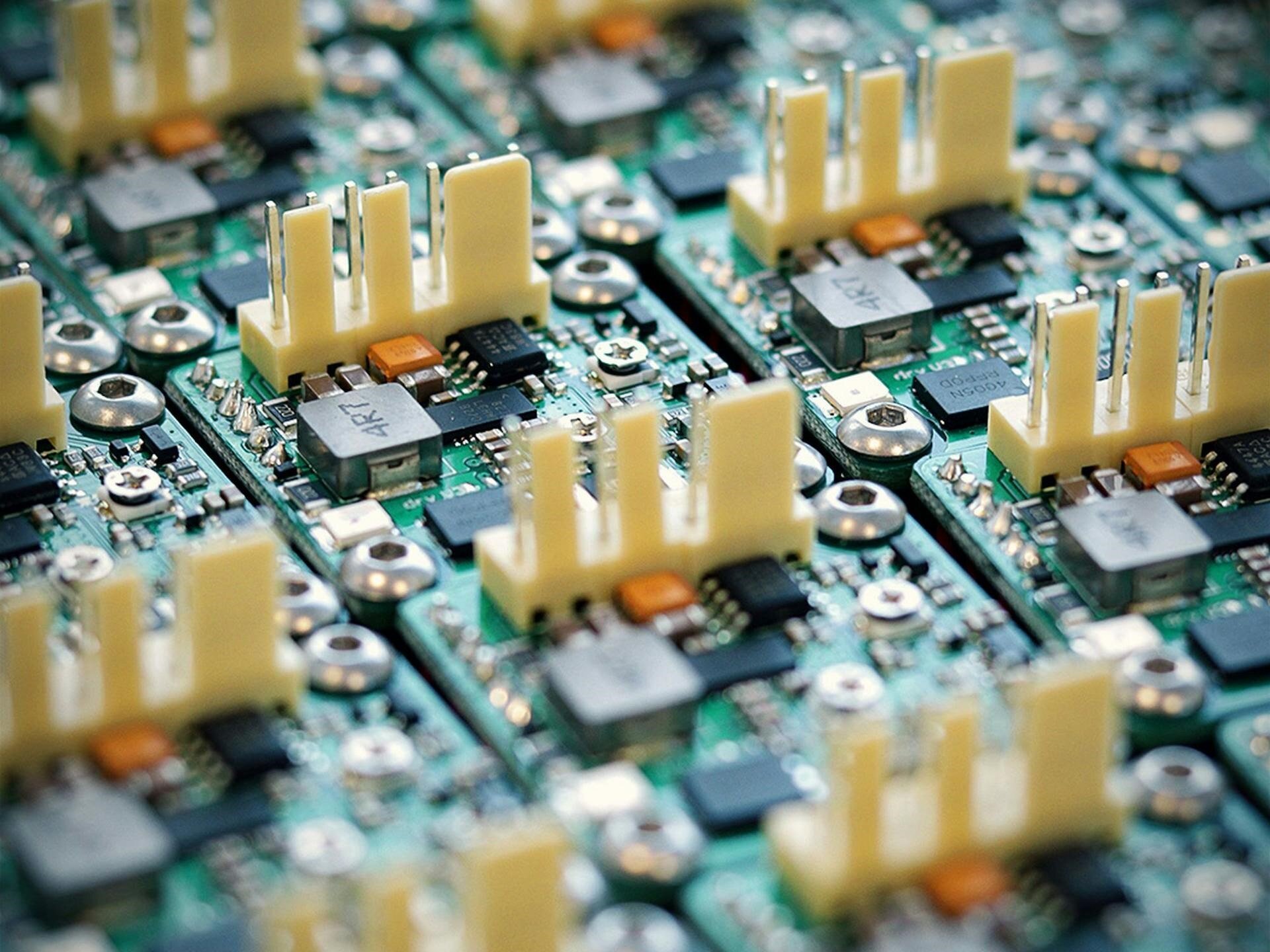

2. Smarter Sourcing Practices

It’s wise to diversify your suppliers and work with hybrid distribution channels to cut costs and improve supply chain resilience.

- Hybrid Sourcing Strategies: A mix of authorized distributors and trusted independent suppliers offers you both reliability and cost savings.

- Alternative Component Selection: Finding functionally equivalent parts prevents production delays and minimizes inflated prices.

- Volume Purchasing Agreements: When you are able to negotiate bulk deals or long-term contracts, you achieve more stable pricing and also reduce per-unit costs.

3. Optimized Logistics and Procurement

Logistics inefficiencies drive up costs through excessive lead times, avoidable shipping fees, and reactive decision-making. Lean into proactive supply chain planning to head off these problems before they arise.

- Consolidated Shipments: Bundle multiple orders into fewer shipments whenever possible to lower freight costs.

- Regional Warehousing: Store parts closer to manufacturing sites to reduce transportation expenses.

- Forecasting and Demand Planning: Advanced planning minimizes last-minute, high-cost sourcing decisions.

Tailored Programs For OEM Supply Chain Optimization

Sensible Micro partners with OEMs to implement targeted supply chain optimization programs, including:

Vendor Inventory Management (VIM)We manage stock levels in response to market conditions and product lifecycles to prevent overages and shortages. |

Alternative Sourcing SolutionsOur network provides cost-effective equivalents to high-priced, obsolete, or unavailable components. |

Market Intelligence & ForecastingSensible Micro supply chain experts analyze component availability and pricing trends to optimize procurement timing. |

Flexible Logistics SupportFrom consolidated shipping to strategic warehousing, our logistics resources help to lower transportation and holding costs. |

The Bottom Line: Smarter Supply Chains, Lower Costs

Supply chain optimization is all about finding efficiencies, ensuring stability, and achieving long-term cost reductions. OEMs can build a more resilient supply chain with improved inventory management and smarter sourcing with the help of an expert supply chain partner.

Get in touch with Sensible Micro to learn how your company can implement supply chain optimization strategies.